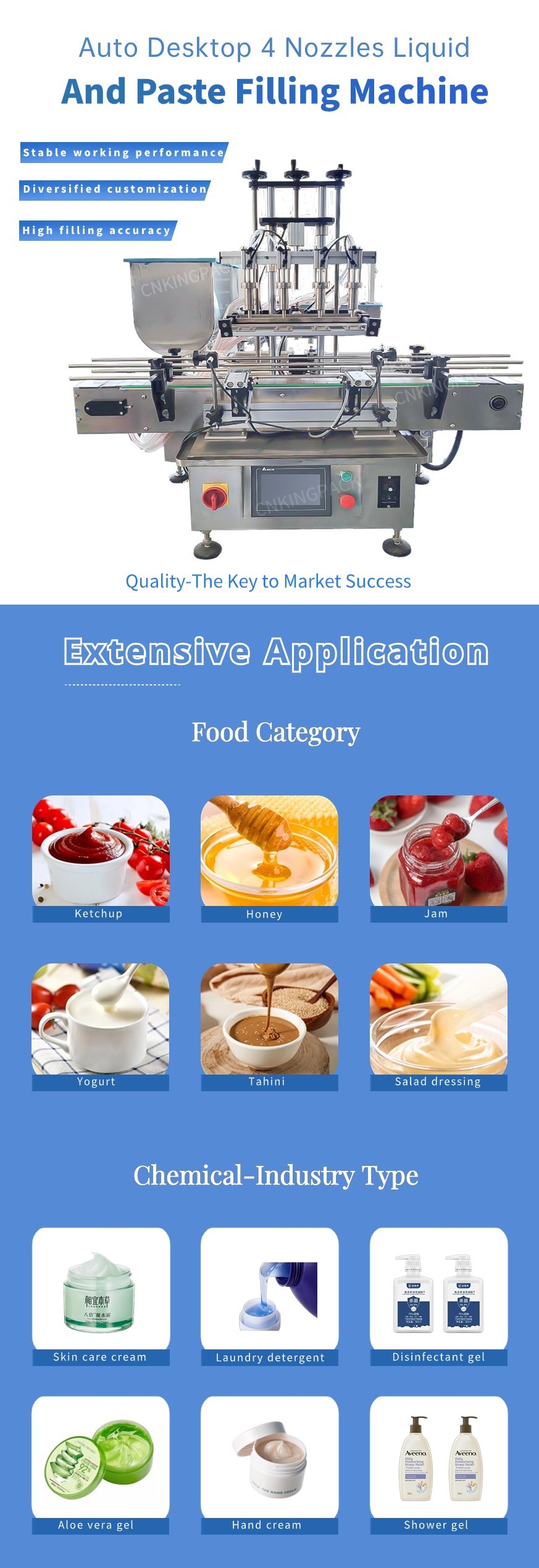

Automatic Desktop Filling Machine TS-4GN

Piston pneumatic Filler is of wide applicability and can be used for doing filling of creams and liquids in the fields of daily chemistry, food and beverage, pharmacy, chemistry and so on.

Description

Designed for filling paste or thick liquid,this machine can work with desktop capping machine and labeling machine to save your working space and improve your production efficiency.Each nozzle of this machine can be controlled separately,we can customize multiple filling nozzles as your production need.

Features

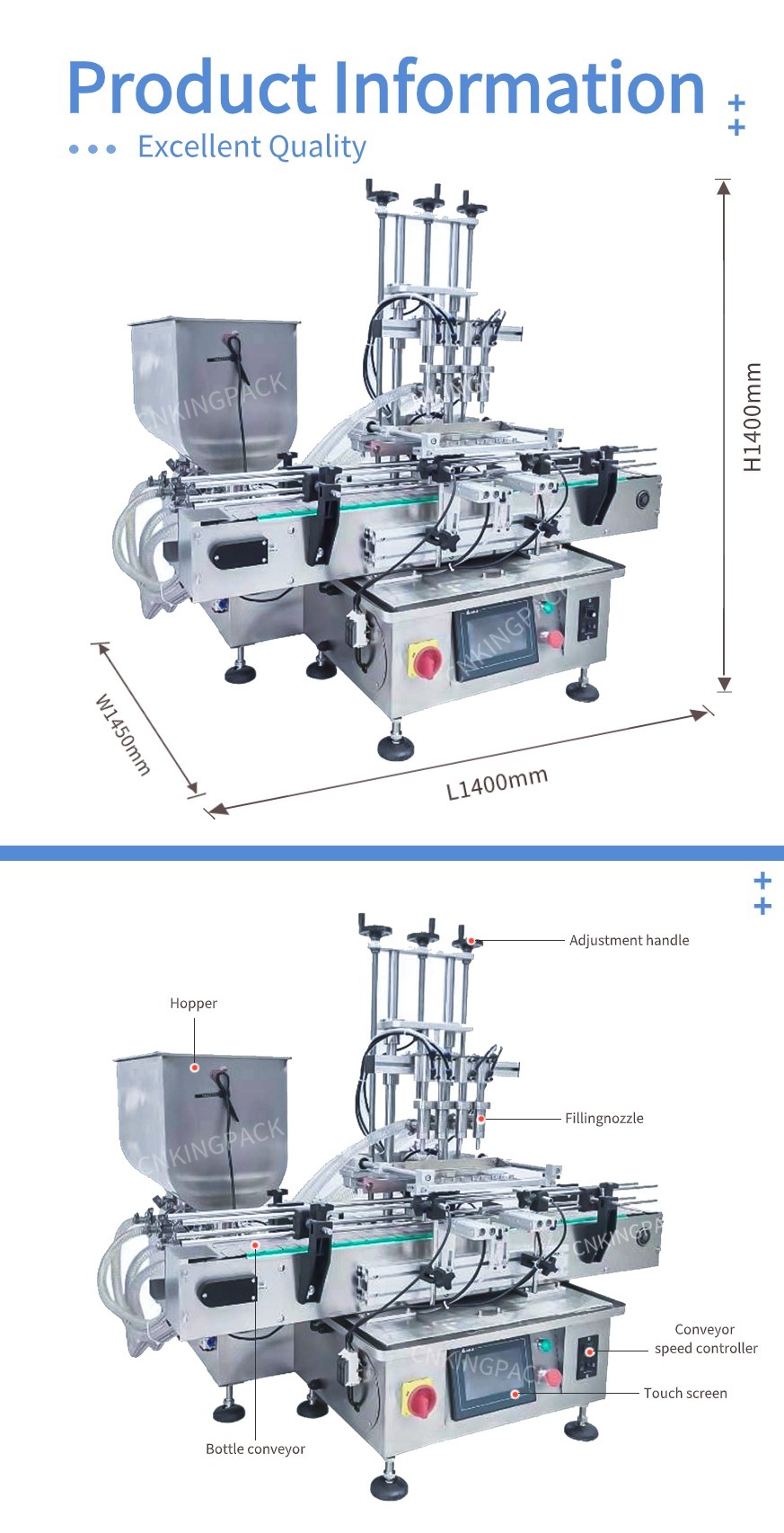

- 01Equipped with the pneumatic filling nozzle, which has larger power and can improve filling speed when fill thicker liquid.There is a anti-dripping slot, it can ensure the production cleanliness.The bottle clamping plate will fixed bottles, this prevent that bottles fall down during filling.

- 02Equipped with 90L large hopper,this better for making the liquid flow faster and can feed filling material in time,improves working speed.

- 03The filling volume can be adjusted by the black rotary knob.Through the small knob to adjust the air intake and air output, you can indirectly control the filling speed and waiting time of the machine.

- 04Designed with PLC touch screen control panel, the digital display makes the working data be visual and can watch the working status of the machine in real time,reduce production error.

|

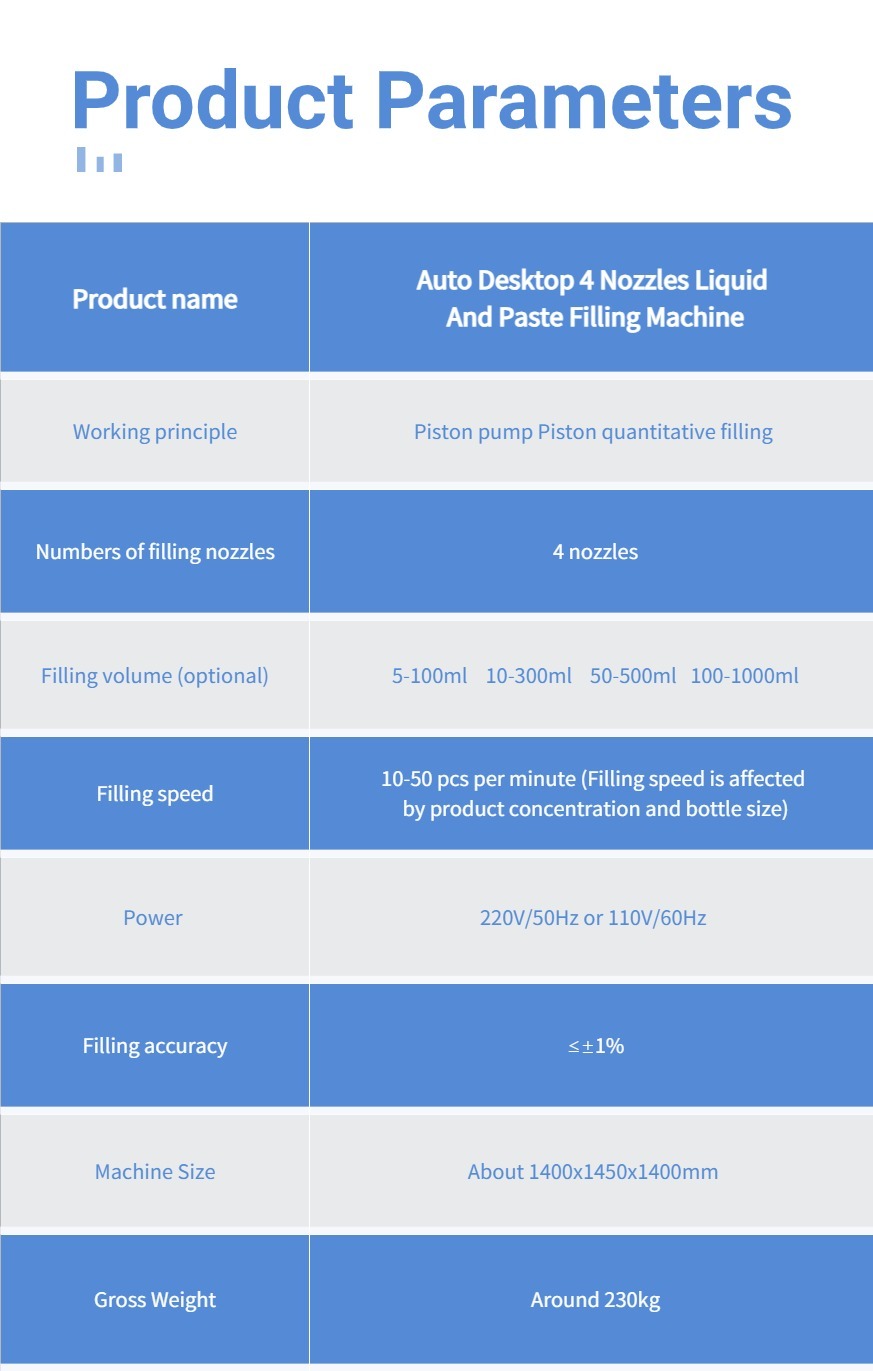

Machine name |

Auto desktop 4 nozzles liquid and paste filling machine |

|

Working principle |

Piston pump Piston quantitative filling |

|

Numbers of filling nozzles |

4 nozzles |

|

Filling volume (optional) |

5-100ml 10-300ml 50-500ml 100-1000ml |

|

Filling speed |

10-50 pcs per minute (Filling speed is affected by product concentration and bottle size) |

|

Power |

220V/50Hz or 110V/60Hz |

|

Filling accuracy |

≤±1% |

|

Machine Size |

About 1400x1450x1400mm |

|

Gross Weight |

Around 230kg |