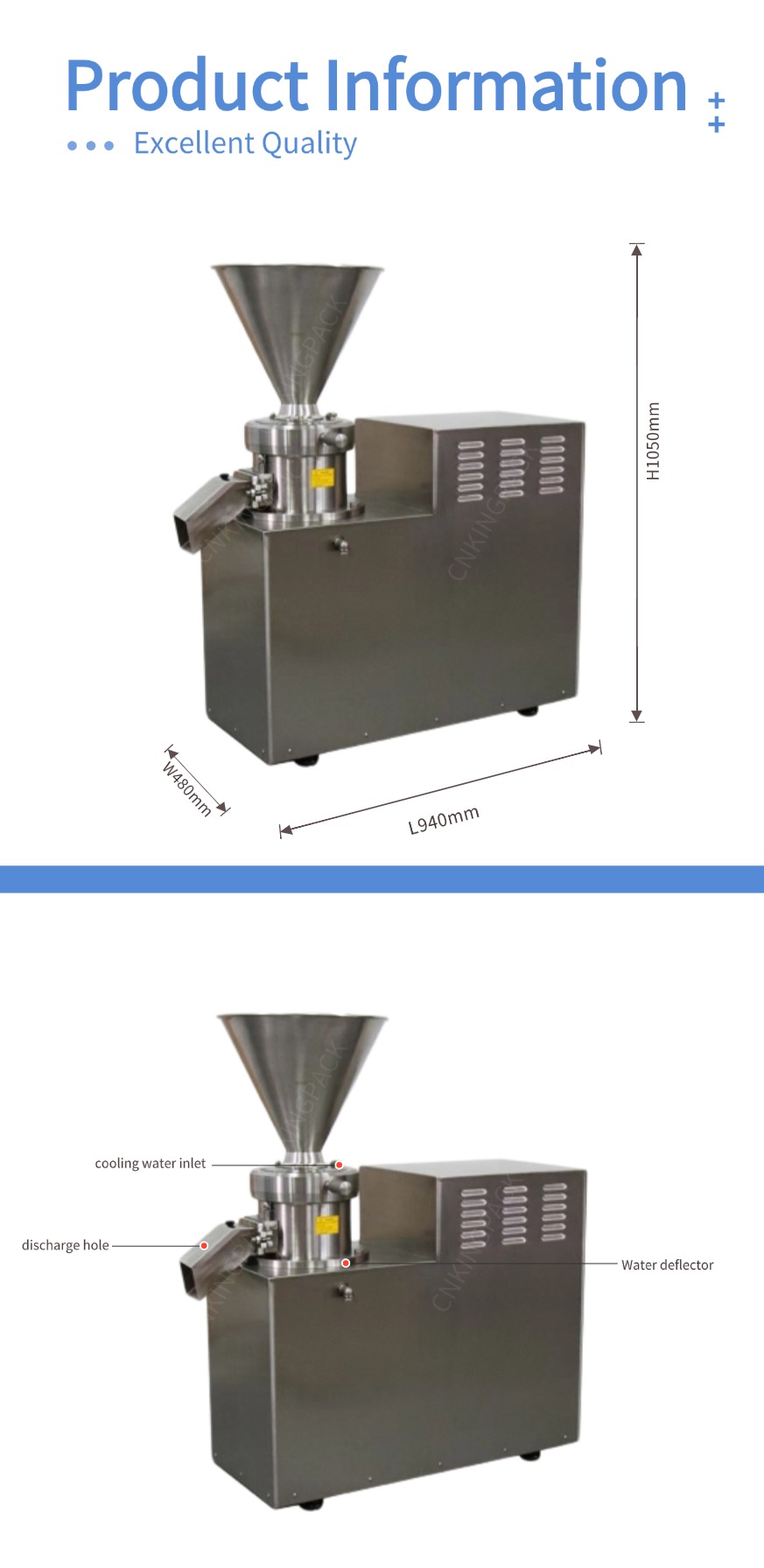

JMS series split colloid mill

Through the relative movement of the dynamic and static grinding plates with different geometries, the processed materials are subjected to strong shear, friction, impact, high-frequency vibration, vortex and other composite forces under the action of pneumatic force and centrifugal force. The materials are effectively dispersed, broken, emulsified, homogenized and evenly mixed, so as to obtain ideal refined products.

Description

Through the relative movement of the dynamic and static grinding plates with different geometries, the processed materials are subjected to strong shear, friction, impact, high-frequency vibration, vortex and other composite forces under the action of pneumatic force and centrifugal force. The materials are effectively dispersed, broken, emulsified, homogenized and evenly mixed, so as to obtain ideal refined products.

Features

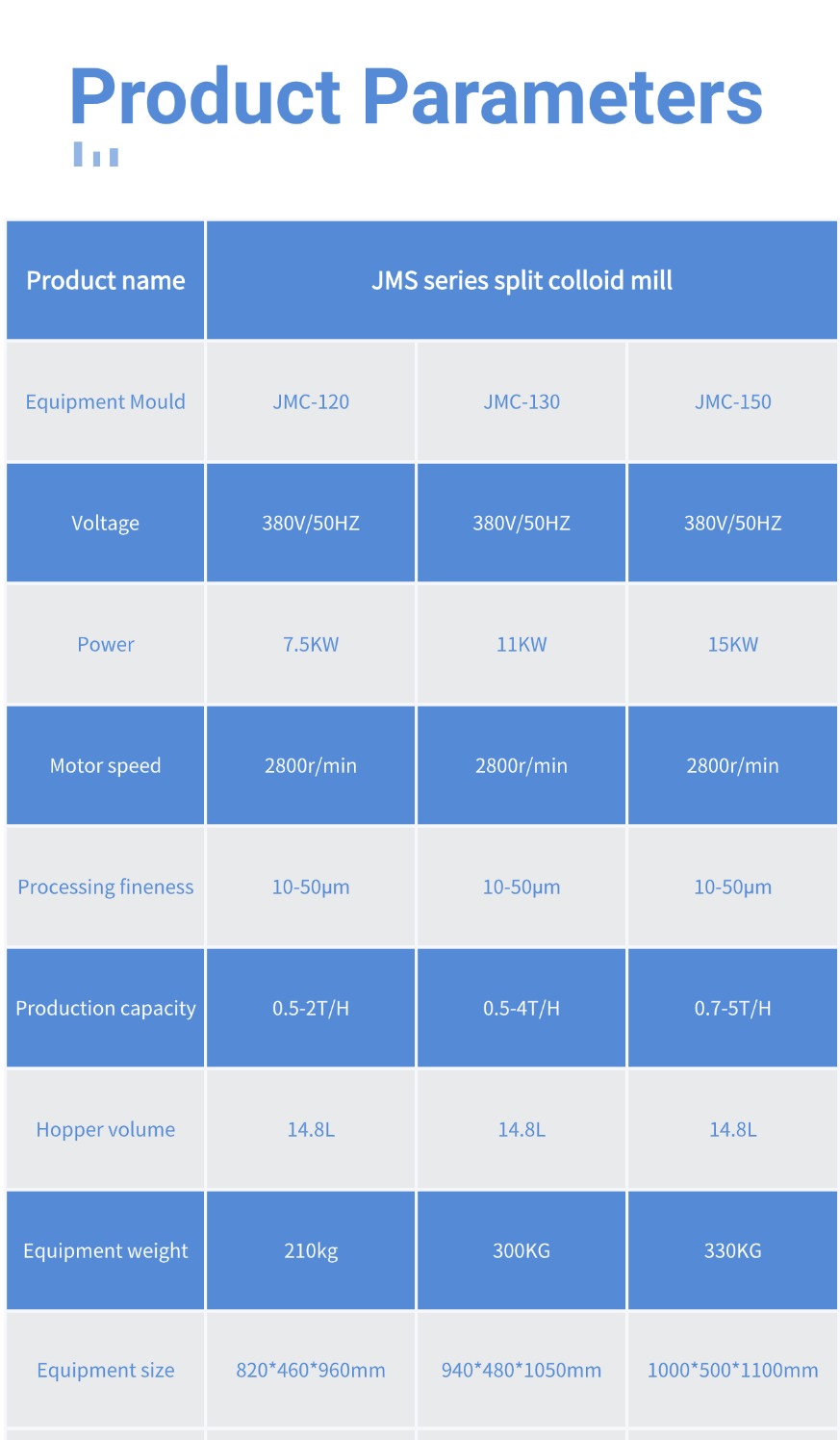

| Product name | JMS series split colloid mill | ||

| Equipment Mould | JMC-120 | JMC-130 | JMC-150 |

| Voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Power | 7.5KW | 11KW | 15KW |

| Motor speed | 2800r/min | 2800r/min | 2800r/min |

| Processing fineness | 10-50μm | 10-50μm | 10-50μm |

| Production capacity | 0.5-2T/H | 0.5-4T/H | 0.7-5T/H |

| Hopper volume | 14.8L | 14.8L | 14.8L |

| Equipment weight | 210kg | 300KG | 330KG |

| Equipment size | 820*460*960mm | 940*480*1050mm | 1000*500*1100mm |